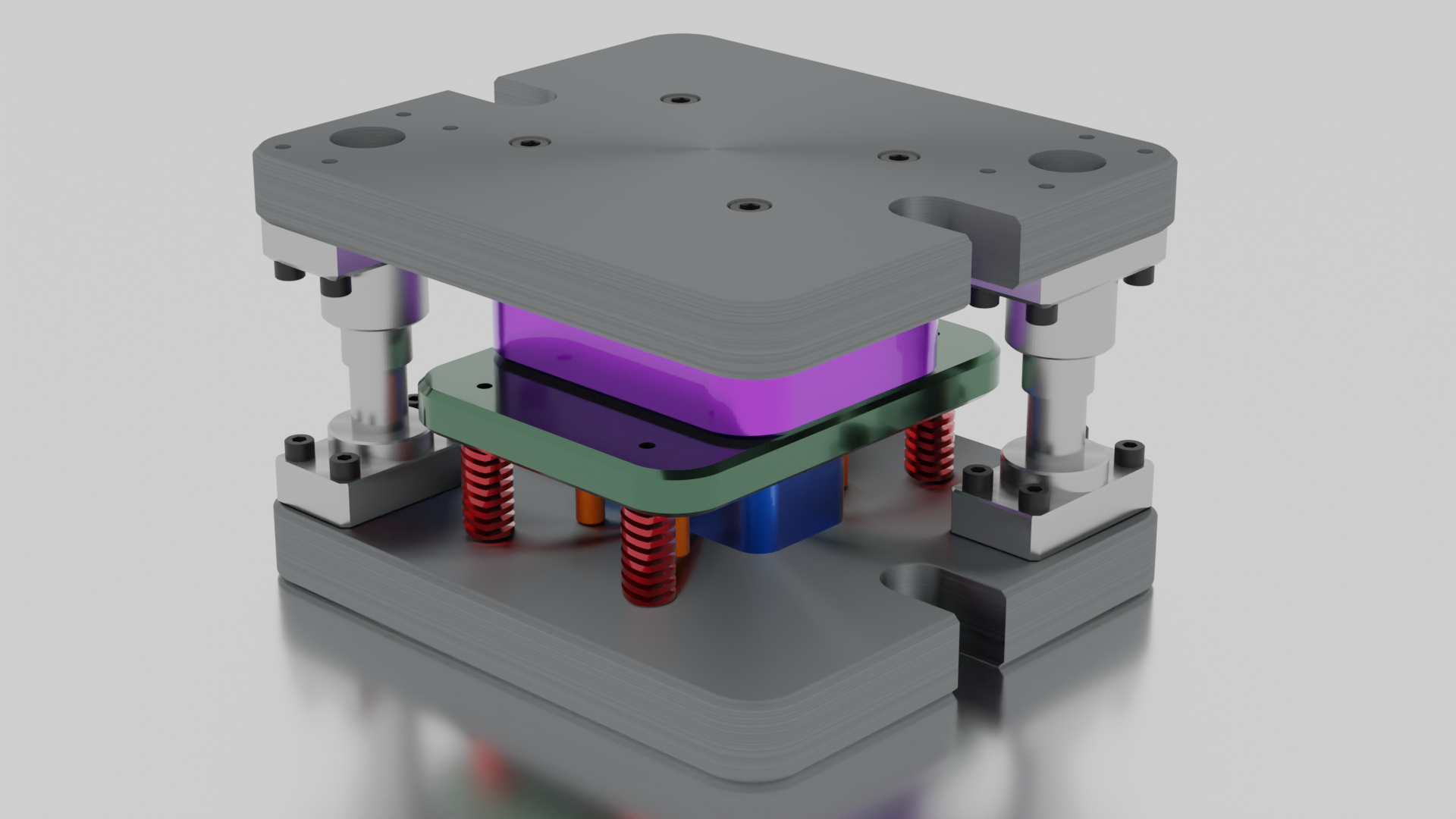

Press Tool Design

Pressing & stamping is a key process in the manufacture and production of sheet metal parts. With many years of industry experience and degree level training, I carry the knowledge to develop tooling to effectively form your sheet metal components. This depth of experience allows nearly all levels of press tool design to be confidently undertaken.

After modelling, press tool designs can be exported and delivered in solid model formats that are suitable to be imported and programmed directly into CNC machines, ready for manufacture.

TYPES OF TOOLING

CRASH TOOLS

A crash tool will be made up of two parts, a Punch and a Die. These are a simple stamping tool where the sheet metal part is hit into its shape, with no control of how the material will move or flow. Crashing parts will commonly lend itself to more simple pressings where blank control isnt critical.

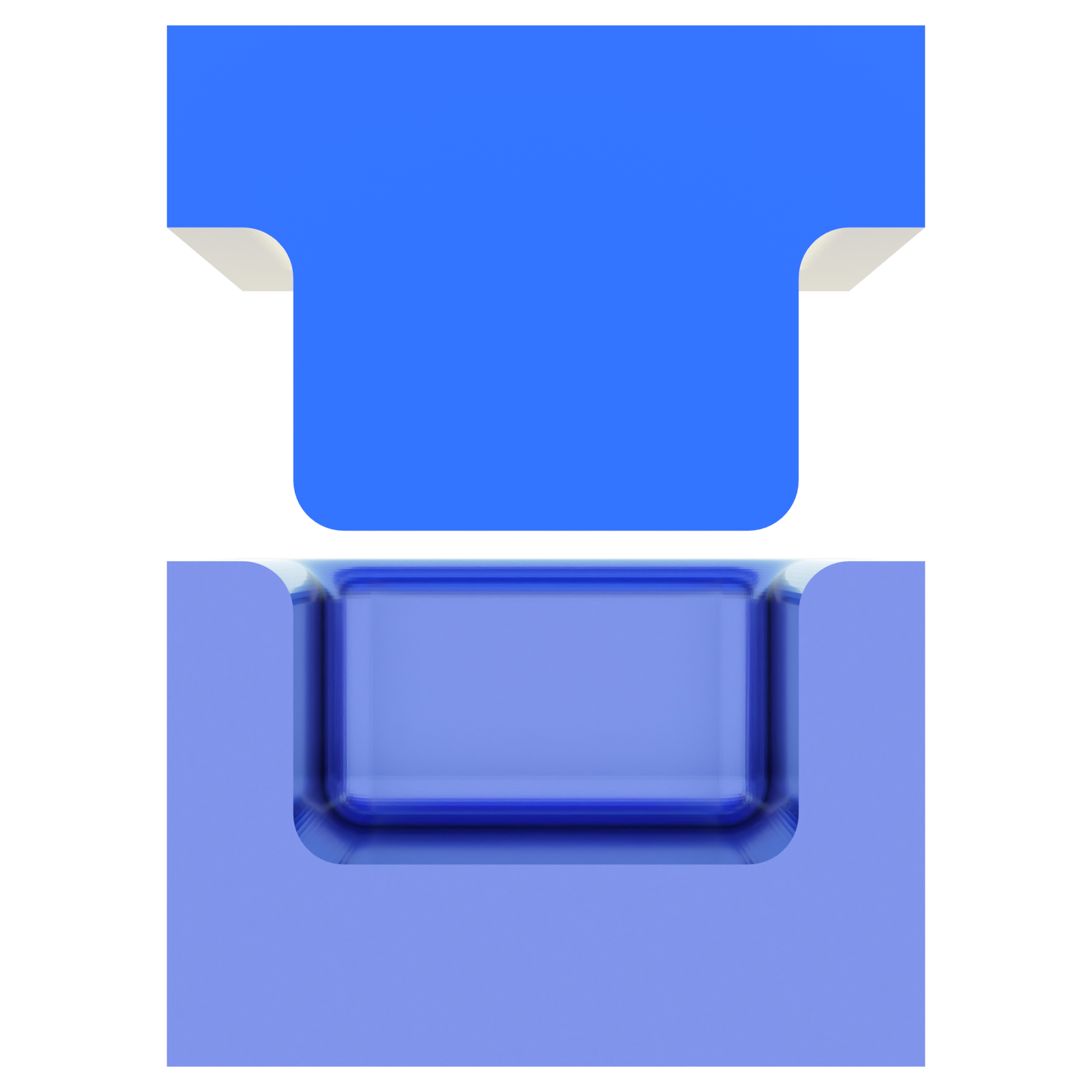

DRAW TOOLS

A Punch, Die and a Binder Ring make up the allignment of a three part draw tool. The Ring will be controlled, vertically, on gas springs or a presses air pins. The blank will then be clamped between the Die and Ring, before the Punch makes contact and the material can flow into its form. The clamped sheet will be under tension allowing more control as it draws into the Die. A draw tool is best suited to deeper and more complicated pressings where there is a lot of potential for material to flow in different directions.

WIPE UP TOOLS

Like a draw tool, a wipe up tool is also made up three parts and has an element controlled on springs. These types of tooling are made up of a Punch, Ring and a Pad. The Pad makes up the central portion of the lower tool and is controlled on air pins. The sheet will be clamped, initially, by the Pad and Punch before contacting the Ring and adding form to the perimeter of the sheet. A Wipe Up tool is best suited to flanging operations.