Reverse Engineering

The past can provide a wealth of knowledge when looking to create designs for the future. Looking to existing designs is a great way of drawing inspiration or creating a base to develop your project from. By reverse engineering an existing design I am able to create a CAD model that can be modified, re-designed or built up on.

Whether you come to me with a physical item, technical drawing or Stl. scan, I will be able to develop usable surface data ready to be integrated into the design or manufacture of your vision…

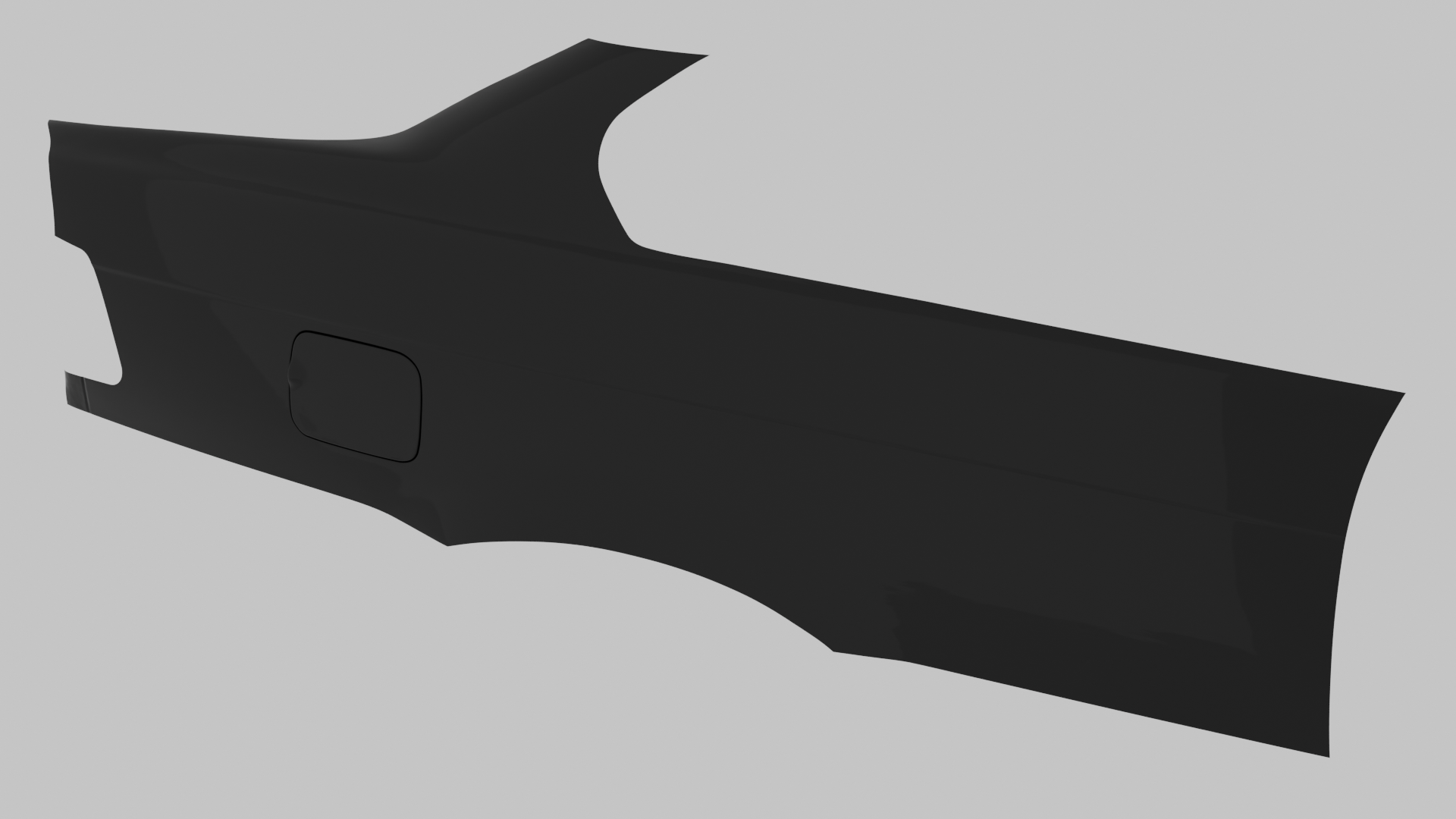

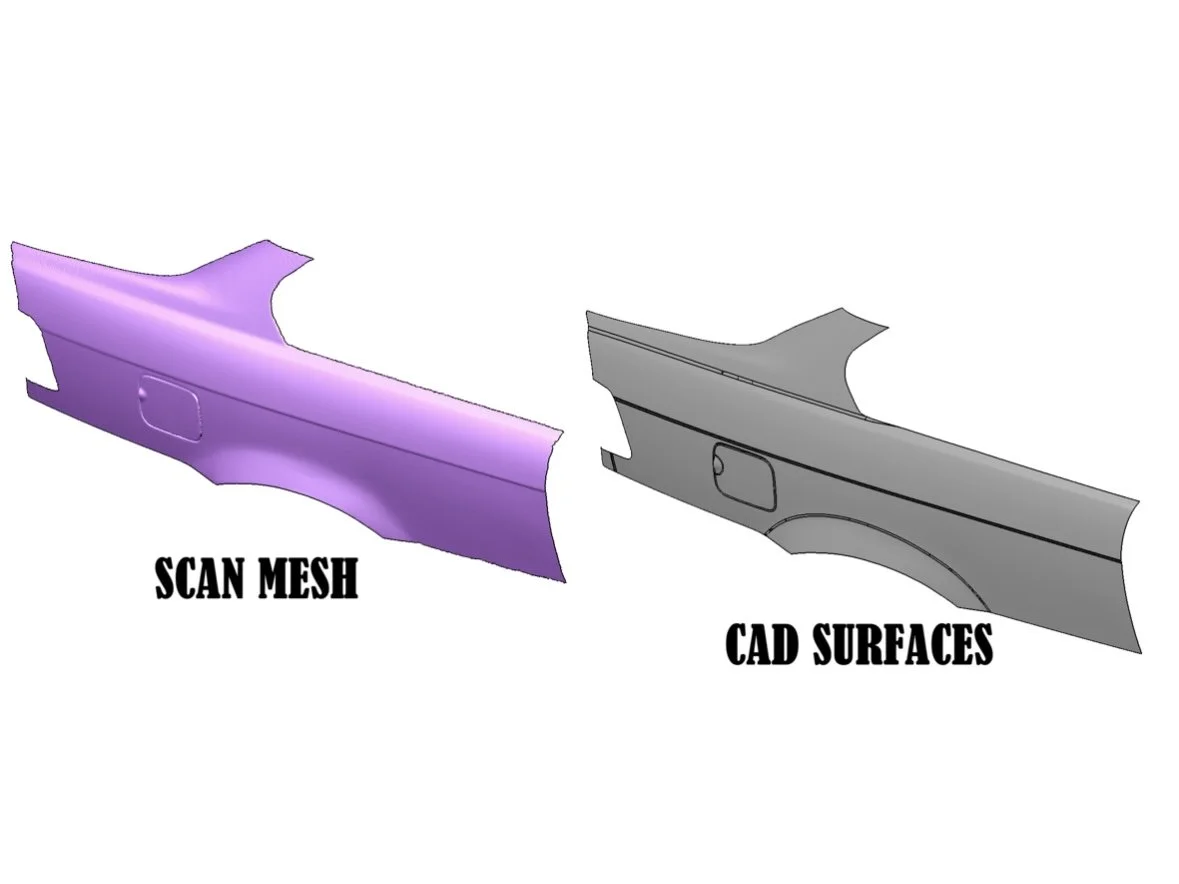

The most common reverse engineering enquiry regards the conversion of 3D scan data. After a physical part has been scanned, the output data comes in the form of a point cloud mesh. This mesh can be imported into CAD software but cannot be used for anything more than a reference and has no functioning data in terms of the 3D CAD worlds. At HUDCAD, I posses the specialist skills, carrying over ten years of industry experience, and licensed software to be able to re-draw and reverse engineer the mesh data into function CAD surfaces and parametric models to an OEM standard, that you would have expected from the original CAD model, prior to manufacture.

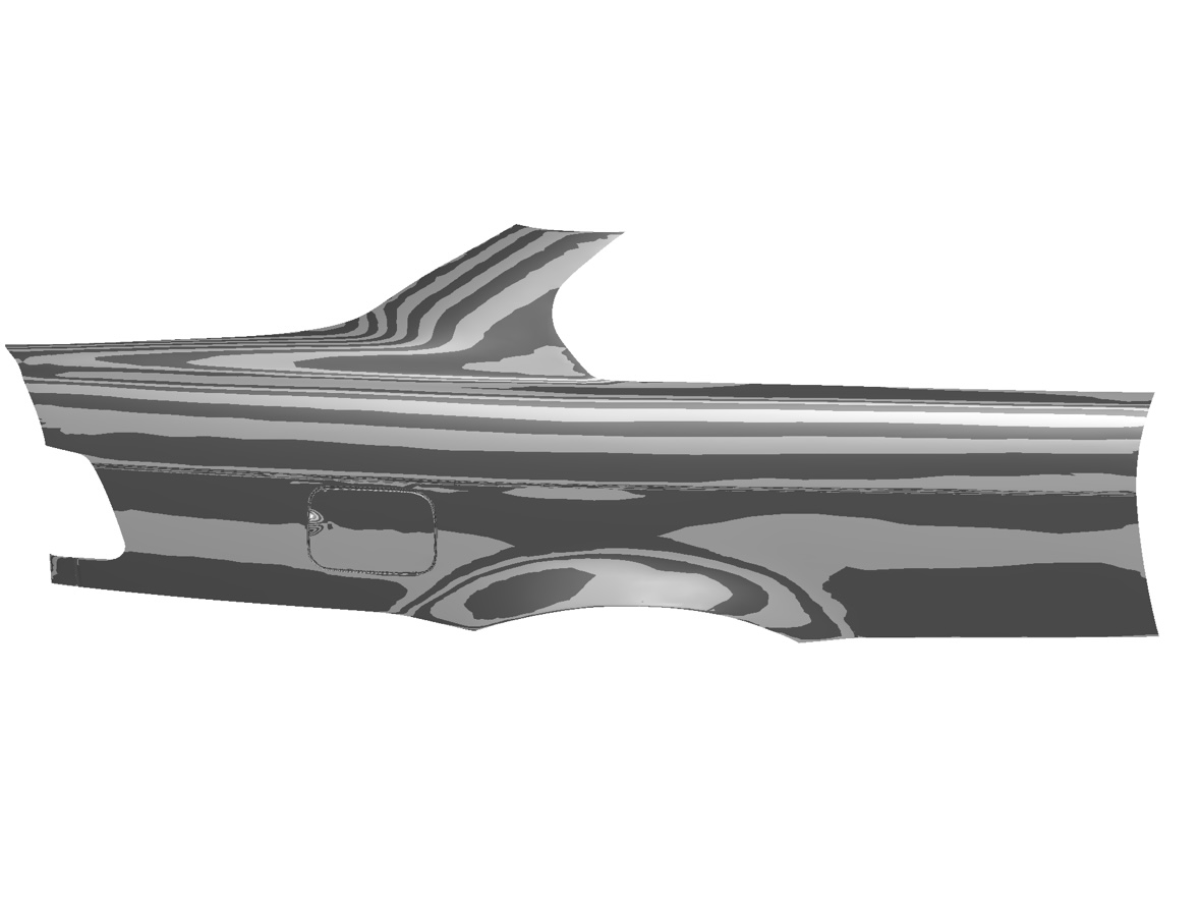

Using some of the latest in industry leading software, I am able to provide quantitative data, alongside complete CAD models, to guarantee minimum deviation from the scan at a high quality to suit whether you are looking Class A, B or C level surfaces.